Yalın Çözüm olarak, Time Prism’in Avrupa ve Amerika’daki tek resmi satış temsilcisiyiz ve 3000’den fazla dünya çapında, 50’den fazla Türkiye’de lisanslı kullanımıyla işletmelerin gelişimine katkıda bulunuyoruz.

-

ITOB Organize Sanayi Bölgesi

10019 Sok. No:6 Menderes / Izmir

-

+90 232 335 35 23

Bizi Arayın

-

+90 532 302 29 23

GSM & Whatsapp

KAIZEN and Industrial Solutions

As Yalın Çözüm, we integrate the KAIZEN philosophy—focused on continuous improvement in production processes—with the specialized industrial solutions we offer through our 4Ever Machinery brand. Within this scope, we provide both consultancy and custom machinery manufacturing services to help businesses increase efficiency, reduce costs, and sustain quality.

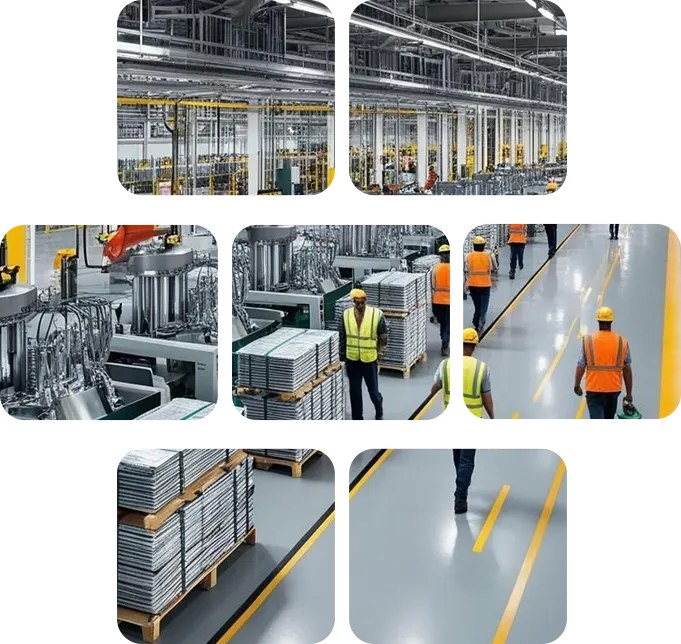

Industrial Solutions Aligned with Kaizen

We implement and standardize solutions that bring new energy and style to your business, preserving existing assets through structuring and integrations that simplify the entire process.

Prevent Errors at Their Source

With Poka-Yoke systems, you prevent operator errors before they occur, minimizing quality loss.

Ensure consistency in processes.

With Standard Work, everyone works the same way, making efficiency and quality standardized.

Reduce Human Error

By delegating repetitive tasks to machines with automation solutions, you reduce error rates and increase workplace safety.

Gain speed with machines specially designed for production.

Shorten production times and increase your competitive edge with machines specially developed for your needs.

Reduce Operational Costs

Solutions supported by both lean approach and technology reduce waste and lower cost per unit.

Achieve Real-Time Control on the Field

With Kaizen-based process management and machine-assisted automation, you gain ease of real-time intervention and control on the field.

Increasing efficiency, reducing errors, and continuously improving production processes is no longer an exclusive privilege for large enterprises. With lean manufacturing solutions based on the KAIZEN philosophy, we enable sustainable growth in your workplace. While guaranteeing quality at the source with error-preventive systems like Poka-Yoke, we ensure consistency in processes through Standard Work practices. On the industrial side, we reduce human errors and boost your production speed with custom-designed machines and automation solutions tailored to your business. With all these solutions, we lower operational costs while enabling real-time control and high agility on the field. Together, through the KAIZEN approach, we build a production culture where machines, processes, and people evolve in harmony.