Yalın Çözüm olarak, Time Prism’in Avrupa ve Amerika’daki tek resmi satış temsilcisiyiz ve 3000’den fazla dünya çapında, 50’den fazla Türkiye’de lisanslı kullanımıyla işletmelerin gelişimine katkıda bulunuyoruz.

-

ITOB Organize Sanayi Bölgesi

10019 Sok. No:6 Menderes / Izmir

-

+90 232 335 35 23

Bizi Arayın

-

+90 532 302 29 23

GSM & Whatsapp

Lean Manufacturing Management

Lean manufacturing is essentially a production system aimed at creating maximum customer value by reducing waste and optimizing processes. It was first developed in Japan, particularly within the Toyota Production System, and has since been adopted across many industries worldwide.

Benefits of Lean Manufacturing

We implement and standardize solutions that bring a new spirit and style to your business, preserving the existing structure while organizing and integrating to simplify the entire process.

Organized Spaces, Continuous Improvement

By simplifying the workplace, we eliminate waste. With 5S, we create an orderly working environment, while with the Kaizen culture, we aim to do better every day.

Uniform Application, Consistent Quality

By standardizing best practices in operational processes, we increase both quality and efficiency while minimizing variability.

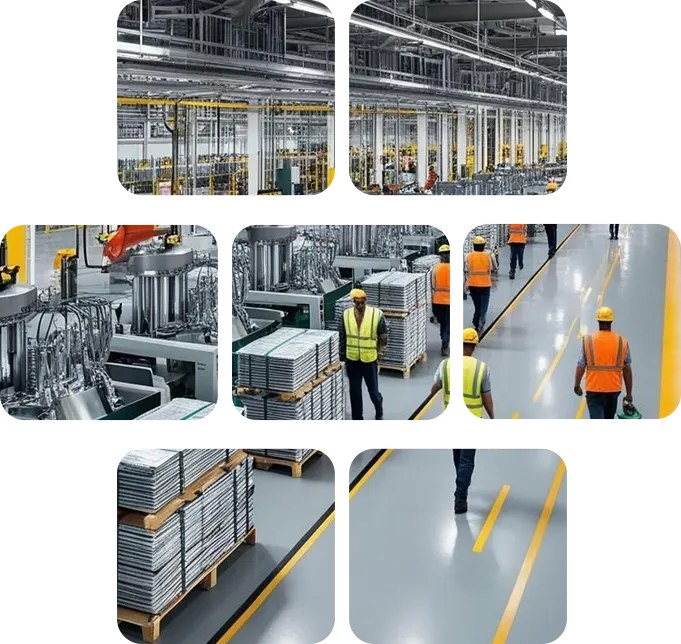

Go to the Field, See the Reality

We bring leaders directly to the production floor. By observing problems on-site, we develop solutions based on real data.

Hours Saved in Minutes

We reduce mold and model changeover times to minimize machine downtime, enabling flexible and fast production, thus increasing efficiency.

Management Becomes Easier as Information is Visualized

With boards and visual tools where all employees can instantly see process performance, we raise awareness and responsibility.

Instant Information, Rapid Response

We make issues on the production line immediately visible to enable quick reactions, reduce downtime, and improve quality.

Increasing efficiency, standardizing quality, and eliminating waste in production processes are more important than ever in today’s competitive world. As Lean Solution, we systematically implement proven lean manufacturing practices starting from the basics to help you achieve these goals.

With the fundamental 5S practice, we organize work areas to be clean, safe, and efficient. Then, we spread continuous improvement throughout the organization with the Kaizen culture. This is not just a technical process but a mindset and culture. Through Standard Work practices, we ensure that best practices are performed uniformly in every operation, preventing both quality deviations and workplace accidents.

Using the SMED (Single Minute Exchange of Dies) method, we significantly reduce downtime and increase production flexibility. With Gemba Walks, we bring managers directly to the production floor to build a culture of real-time observation and intervention. This ensures problems are solved on the floor, not in offices. Visual Management tools create environments where all employees can instantly follow processes and enhance awareness and accountability.

At an advanced level, we ensure errors are prevented before they occur with Poka-Yoke (Error Proofing), systematically securing quality. With Heijunka (Production Leveling), we balance production against demand fluctuations, preventing excess inventory or bottlenecks. Additionally, Value Stream Mapping analyzes the entire process end-to-end, identifying non-value-adding steps and clearly revealing improvement opportunities.

Our fundamental approach in every implementation is clear:

Observe on-site, analyze based on data, simplify, apply, and continuously improve.

With solutions tailored to your business structure and needs, we make lean thinking not just a project but an integral part of your corporate culture.